UK LASER AND PRINT

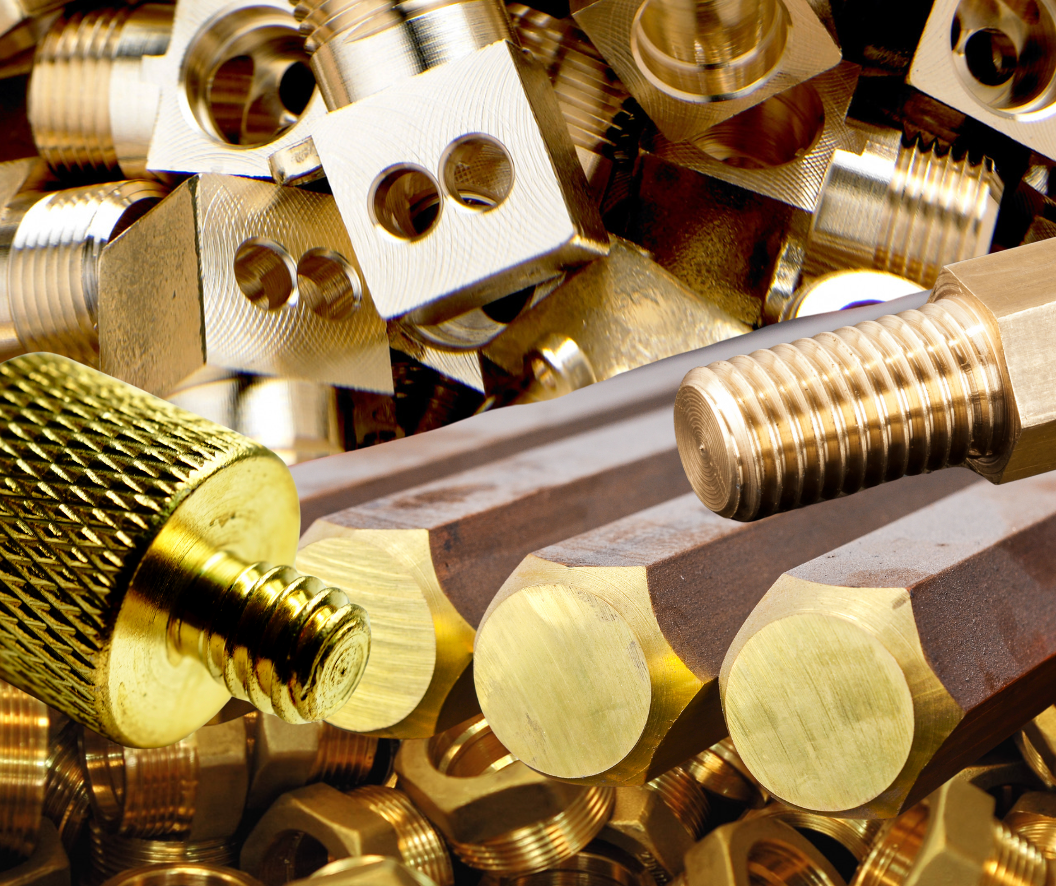

Brass Lathe Service Grooving Drilling Knurling Boring Threading Bushes

Brass Lathe Service Grooving Drilling Knurling Boring Threading Bushes

Couldn't load pickup availability

Brass Lathe Service Grooving Drilling Knurling Boring Threading Bushes

Brass Lathe Service Grooving Drilling Knurling Boring Threading Bushes Lathe Operations:Precision Turning: Shafts and Rods: Colchester lathes excel at turning cylindrical workpieces, such as steel shafts or aluminum rods. Tapers and Threads: Create precise tapers for machine components or cut accurate threads for bolts and nuts. 1. Custom Parts Manufacturing:o Prototypes: Craft one-off parts for testing and development.o Replacement Components: Machine unique pieces to replace worn-out or broken parts in machinery.2. Tool and Die Making:o Molds and Dies: Shape molds for plastic injection or die-casting processes.o Forming Tools: Create dies for sheet metal bending or stamping.3. Repair and Restoration:o Machine Maintenance: Repair worn-out components in existing machinery.o Vintage Restoration: Restore antique parts or components.4. Education and Training:o Apprenticeships: Train new machinists on manual lathe operations.o Technical Schools: Teach students the fundamentals of machining.5. Artistic Creations:o Woodturning: Craft wooden bowls, vases, or artistic pieces.o Metal Sculptures: Turn metal blocks into intricate sculptures.6. Small Batch Production:o Short Production Runs: Manufacture small quantities of specialized components efficiently. contact wes on - 07938952122 8am to 8pm email inquires at - enquires@heywoodmachiningservices.co.uk Lathe Operations:Precision Turning:Shafts and Rods: Colchester lathes excel at turning cylindrical workpieces, such as steel shafts or aluminium rods.Tapers and Threads: Create precise tapers for machine components or cut accurate threads for bolts and nuts.Custom Parts Manufacturing:Prototypes: Craft one-off parts for testing and development.Replacement Components: Machine unique pieces to replace worn-out or broken parts in machinery.Tool and Die Making:Moulds and Dies: Shape moulds for plastic injection or die-casting processes.Forming Tools: Create dies for sheet metal bending or stamping.Repair and Restoration:Machine Maintenance: Repair worn-out components in existing machinery.Vintage Restoration: Restore antique parts or components.Education and Training:Apprenticeships: Train new machinists on manual lathe operations.Technical Schools: Teach students the fundamentals of machining.Artistic Creations:Woodturning: Craft wooden bowls, vases, or artistic pieces.Metal Sculptures: Turn metal blocks into intricate sculptures.Small Batch Production:Short Production Runs: Manufacture small quantities of specialized components efficiently.Brass Lathe Service Grooving Drilling Knurling Boring Threading Bushes

Lathe Operations:Precision Turning: Shafts and Rods: Colchester lathes excel at turning cylindrical workpieces, such as steel shafts or aluminum rods. Tapers and Threads: Create precise tapers for machine components or cut accurate threads for bolts and nuts. 1. Custom Parts Manufacturing:o Prototypes: Craft one-off parts for testing and development.o Replacement Components: Machine unique pieces to replace worn-out or broken parts in machinery.2. Tool and Die Making:o Molds and Dies: Shape molds for plastic injection or die-casting processes.o Forming Tools: Create dies for sheet metal bending or stamping.3. Repair and Restoration:o Machine Maintenance: Repair worn-out components in existing machinery.o Vintage Restoration: Restore antique parts or components.4. Education and Training:o Apprenticeships: Train new machinists on manual lathe operations.o Technical Schools: Teach students the fundamentals of machining.5. Artistic Creations:o Woodturning: Craft wooden bowls, vases, or artistic pieces.o Metal Sculptures: Turn metal blocks into intricate sculptures.6. Small Batch Production:o Short Production Runs: Manufacture small quantities of specialized components efficiently. contact wes on - 07938952122 8am to 8pm email inquires at - enquires@heywoodmachiningservices.co.uk

Lathe Operations:

Precision Turning:

-

Shafts and Rods: Colchester lathes excel at turning cylindrical workpieces, such as steel shafts or aluminium rods.

-

Tapers and Threads: Create precise tapers for machine components or cut accurate threads for bolts and nuts.

-

Custom Parts Manufacturing:

-

Prototypes: Craft one-off parts for testing and development.

-

Replacement Components: Machine unique pieces to replace worn-out or broken parts in machinery.

-

-

Tool and Die Making:

-

Moulds and Dies: Shape moulds for plastic injection or die-casting processes.

-

Forming Tools: Create dies for sheet metal bending or stamping.

-

-

Repair and Restoration:

-

Machine Maintenance: Repair worn-out components in existing machinery.

-

Vintage Restoration: Restore antique parts or components.

-

-

Education and Training:

-

Apprenticeships: Train new machinists on manual lathe operations.

-

Technical Schools: Teach students the fundamentals of machining.

-

-

Artistic Creations:

-

Woodturning: Craft wooden bowls, vases, or artistic pieces.

-

Metal Sculptures: Turn metal blocks into intricate sculptures.

-

-

Small Batch Production:

-

Short Production Runs: Manufacture small quantities of specialized components efficiently.

-

Share